Offene Stellen

Jetzt anschauenProduction

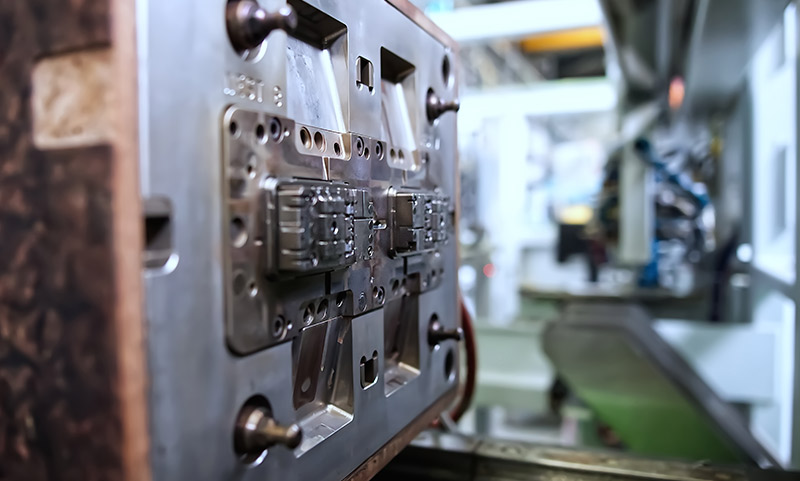

Our injection-moulding machines from 50t to 650t enable us to process the most common thermoplastics into sophisticated moulds. We mainly use the multi-component technology.It is essential to have demanding equipment in order to be able to manufacture top-quality technical plastic components. We fulfill this requirement: from the central fully automatic material supply to the state-of-the-art injection-moulding machines to the removal of the sensititve items using high-quality handling devices.

Our machinery

- 1 component injection moulding machines 50t …650t, DEMAG, Arburg, Engel und Ferromatik

- 2 component injection moulding machines 80t…420t, DEMAG, Arburg, Ferromatik

- 3 component injection moulding machines 70t…180t, Arburg, Ferromatik

- Individual automation lines and CNC Handling Systems

- Motan central material loader for granulate

- Central water treatment

- Temperature control unit up to 160°C

- Ultrasonic welding

- Backup system – 24h guarantee for delivery reliability (emergency plan, emergency systems for all essential supply systems, T90 fire compartments, sprinkler system, fireproof tool warehouse)

- Own modern tool production, maintenance

- Special automation section (gripper, special purpose machines and devices)

- Central PPS system with manufacturing control system and factory data collection

- Central tool warehouse

German

German English

English