Offene Stellen

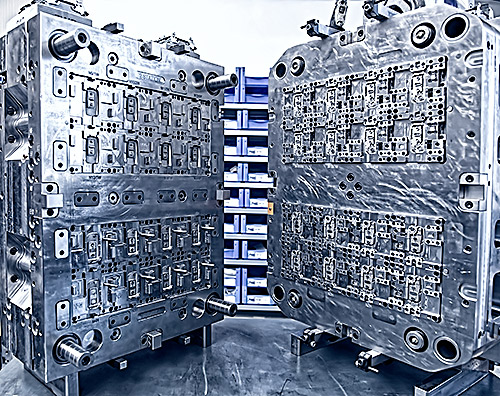

Jetzt anschauenTool manufacturing

According to the specifications of the design department, our tool manufacturing department produces injection-moulding tools as well as jigs and devices using the most up-to-date CAD/CAM and machine technologies. Thanks to our fully air-conditioned eroding and machining centres, we are in a position to manufacture high-precision tools and mould inserts with the smallest tolerances. Our decades’ worth of know-how in tool engineering and tool manufacturing ensure hightest possible quality standards and maximum output (tool life).

Our machinery

Wire-cut EDM:

- GF CUT 2000 S (air-conditioned)

- GF Agiecut Progress 3 (air-donditioned)

Die sinking EDM:

- GF Agietron Innovation 3 (air-conditioned)

- GF AT Hyperspark 2HS (air-conditioned)

Milling:

- Hermle C800V CNC machining centre

- Röders CNC machining centre (air-conditioned)

5-axis – RXP 601 DSH + RCS-3 automation - Röders CNC machining centre (air-conditioned)

5-axis – RXP 800 DS + RC-3 automation

Hole EDM:

- GF DRILL 20 EDM (air-conditioned)

Further machines and equipment:

- Flat grinding machine

- Laser welding

- WIG welding

- Microwelding

- Polishing workstations

- Measuring machine Zeiss Duramax

- Assembly workstations

- Die spotting press

- Ultrasonic cleaning equipment

German

German English

English